Fields of Innovation

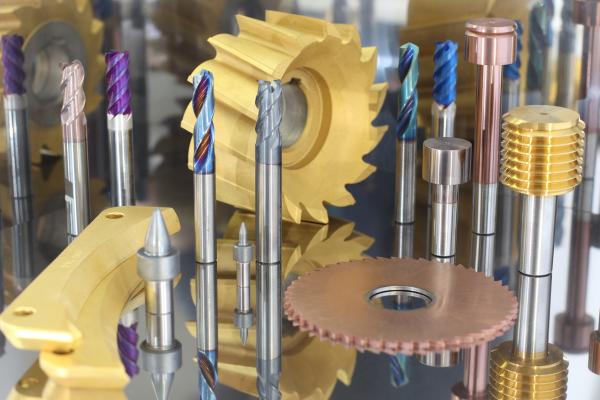

Sustainable Coating Development and Wear Reduction

New approaches are being developed to meet additional and expanded requirements for PVD coatings beyond those of "conventional" PVD coatings. In order to increase the overall service life of coated components, several key tasks have emerged, including:

- Alternative coating materials and application procedures

- Thick coatings with enhanced wear resistance

- Defined wear detection for optimized manufacturing processes

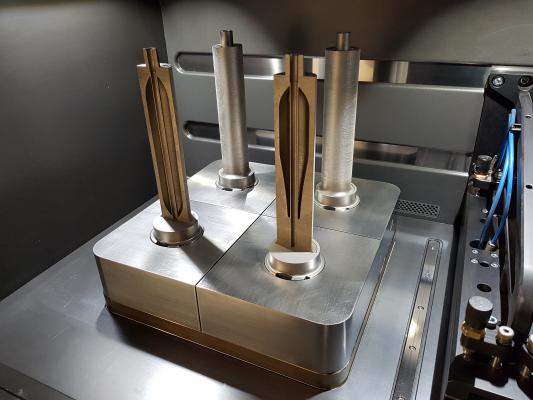

Enhanced Reconditioning and Optimized Resource Efficiency

Reconditioning of coated tools and components is achieved simply by removing the worn coating and applying a new one. This enables a significant increase in the overall service life through reconditioning without the need for additional post-processing of tools or surfaces. Benefits include financial savings and ecological advantages due to reduced resource consumption, as well as a substantial enhancement in production sustainability.

In addition to reconditioning, further tasks need to be addressed, such as:

- Coordination of steps up to recycling and preventive maintenance

- Specific load and wear criteria

- Cyclical use of tools and components

Process Optimization and Smart Automation

We strive to reimagine processes and achieve optimization through resource-efficient technologies and automation. Developing alternative and hybrid process chains, along with leveraging additive manufacturing and laser material processing, are also essential. The primary drivers for advancement in these areas include:

- Creation of a "digital twin" to support process monitoring

- Collection and integration of process data

- Smart utilization of process data for controlling manufacturing processes